TJ-II:Vacuum system

Vacuum vessel

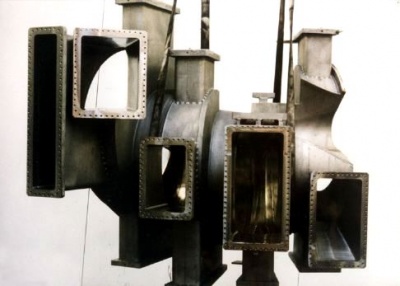

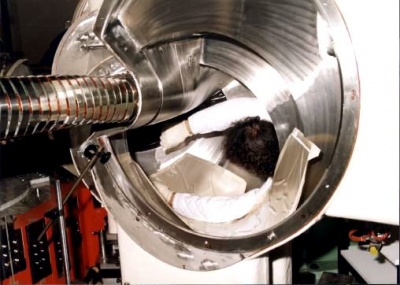

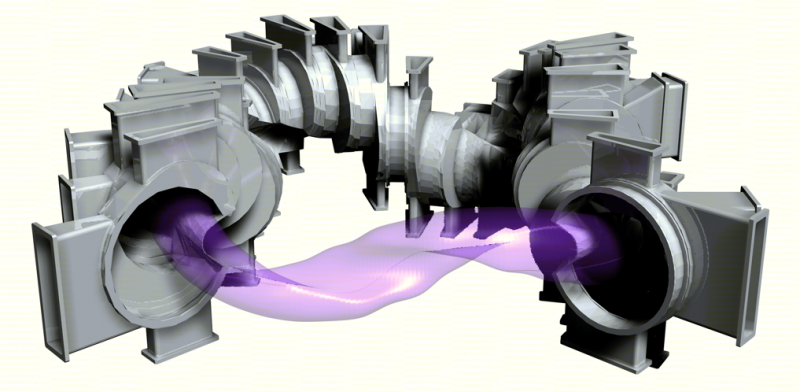

The all-metal TJ-II vacuum vessel has a helical geometry and has 96 ports. [1] [2] The vacuum vessel is made of non-magnetic steel (304 LN) with a thickness of 10 mm. The CC/HX coil is outside of the vacuum vessel thanks to a helical groove built into the vessel. This groove has a wall thickness of 7 mm for clearance reasons. The groove is protected along the entire toroidal circumference against damage due to the bean-shaped plasma by 3 mm stainless steel sheets for low and medium power operation and graphite tiles for high power operation. Furthermore, the vacuum vessel is protected on the areas where the neutral beams deposit a residual shine-through heat flux.

Vacuum system

The vacuum vessel is pumped through four symmetrically spaced bottom ports to a base pressure of 10-8 mbar. Four identical and independent vacuum pumping subsystems are used. [3] [4] [5]

See also

- TJ-II:Plasma Wall Interaction (vessel wall conditioning)

- TJ-II:Sectors (top view of a model of the vacuum vessel)

References

- ↑ M. Baldarelli, A, Cecchini, M, Cucchiaro, et al., Vacuum vessel design for the TJ-II Heliac, Proc. 16th Symposium on Fusion Technology, London, U.K., 3–7 September 1990, 453

- ↑ J. Botija and M. Blaumoser, Vacuum vessel design for the TJ-II device, 14th IEEE/NPSS Symposium on Fusion Engineering 2 (1991) 992-995

- ↑ J. Botija et al, Vacuum vessel, wall protection, pumping system and poloidal limiters of the Spanish stellarator TJ-II, 15th IEEE/NPSS Symposium on Fusion Engineering 1 (1993) 529-532

- ↑ F. Tabarés, The vacuum system of the TJ-II stellarator, Vacuum 45, Issues 10-11 (1994) 1059-1061

- ↑ R. Carrasco, Hybrid baking system for the vacuum vessel of the Spanish stellarator TJ-II, Proc. 18th Symposium on Fusion Engineering (1999) 231-234