TJ-II:Construction: Difference between revisions

No edit summary |

|||

| Line 4: | Line 4: | ||

<ref>[http://dx.doi.org/10.1109/FUSION.1997.687032 M. Blaumoser et al, ''Construction, commissioning and first results of the Spanish Stellarator TJ-II'', Fusion Engineering, Proc. 17<sup>th</sup> IEEE/NPSS Symposium '''1''' (1997) 257 - 260]</ref> | <ref>[http://dx.doi.org/10.1109/FUSION.1997.687032 M. Blaumoser et al, ''Construction, commissioning and first results of the Spanish Stellarator TJ-II'', Fusion Engineering, Proc. 17<sup>th</sup> IEEE/NPSS Symposium '''1''' (1997) 257 - 260]</ref> | ||

<ref>[http://www.ornl.gov/sci/fed/stelnews/pdf/sn48.pdf C. Alejaldre et al, ''TJ-II assembly completed'', Stellarator news '''48''' (1996) 1]</ref> | <ref>[http://www.ornl.gov/sci/fed/stelnews/pdf/sn48.pdf C. Alejaldre et al, ''TJ-II assembly completed'', Stellarator news '''48''' (1996) 1]</ref> | ||

<ref>[[Media:ALONSO.pdf|J. Alonso, ''Design, construction and assembly of the Spanish stellarator TJ-II. Engineering experience'' (2007)]]</ref> | |||

=== Vacuum vessel === | === Vacuum vessel === | ||

Revision as of 11:14, 11 August 2010

TJ-II is a highly flexible medium-size fusion device of the Heliac type constructed at CIEMAT between 1991 and 1997. The magnetic surface mapping was measured at low magnetic fields between December 1996 and January 1997, with excellent results. From January to September 1997 the commissioning of the device up to the design values was done, together with the assembly of the basic diagnostic equipment. [1] [2] [3]

Vacuum vessel

The all-metal TJ-II vacuum vessel has a helical geometry and has 96 ports. [4] The vacuum vessel is made of non-magnetic steel (304 LN) with a thickness of 10 mm. The octants with flanges have been manufactured separately and were assembled in-situ by welding. This assembly was done directly around the central conductor CC/HX, already placed in position. The CC/HX coil is outside of the vacuum vessel thanks to a helical groove built into the vessel.

Coil system

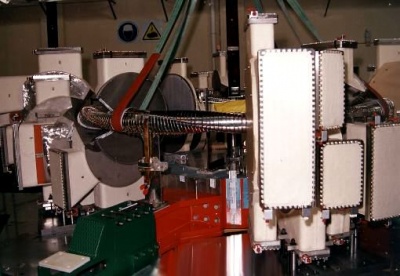

Seven water-cooled copper coil systems with maximum currents between 7 kA and 32.5 kA provide the helical confinement field. The Bitter-type toroidal coils are split in half for assembly reasons. Four sets of poloidal coils produce the vertical, radial and OH fields.

Precision machining and positioning

TJ-II is a very compact experimental device with highly stressed materials and very narrow tolerances to achieve good confinement properties. This required high quality standards for the fabrication and assembly of the device. For the high precision positioning of all stellarator components, a computer-based theodolite system was employed. A large number of tests were done during the assembly phase. Afterwards a comprehensive commissioning program was performed.

Power supply

The pulsed power supply was tested up to the maximum current values by means of a dummy load consisting of up to five inductively coupled coils. The distances between the coils were chosen in a way such that self and mutual inductances coincided with those of the coil systems of the stellarator, thus forming an electromagnetic image of TJ-II.

References

- ↑ M. Blaumoser et al, Construction, commissioning and first results of the Spanish Stellarator TJ-II, Fusion Engineering, Proc. 17th IEEE/NPSS Symposium 1 (1997) 257 - 260

- ↑ C. Alejaldre et al, TJ-II assembly completed, Stellarator news 48 (1996) 1

- ↑ J. Alonso, Design, construction and assembly of the Spanish stellarator TJ-II. Engineering experience (2007)

- ↑ J. Botija and M. Blaumoser, Vacuum vessel design for the TJ-II device, 14th IEEE/NPSS Symposium on Fusion Engineering 2 (1991) 992-995