LNF:Technology: Difference between revisions

Garciacortes (talk | contribs) |

Garciacortes (talk | contribs) |

||

| Line 42: | Line 42: | ||

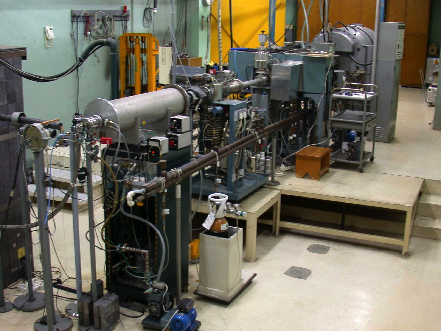

===60 keV DANFYSIK ION IMPLANTER=== | ===60 keV DANFYSIK ION IMPLANTER=== | ||

[[File:Foto0045.jpg|500px|thumb|right| | [[File:Foto0045.jpg|500px|thumb|right|Ion Implanter]] | ||

Revision as of 09:43, 30 October 2015

The main goal of the Fusion Technology Division of the Spanish National Fusion Laboratory is research on the properties as well as the radiation hardness and subsequent degradation of structural and functional materials for future fusion reactors. In particular, studies on reduced activity ferritic/martensitic steels and materials used for electrical isolation, diagnostic windows etc. are central to this work. In parallel, given that at present, there is no neutron source available that simulates the fluxes and energies required for material irradiation under predicted fusion reactor conditions, the division is involved in the development of suitable neutron sources for material irradiation (ENS, IFMIF, and DONES). These sources, when on-line, will facilitate accelerated irradiation damage studies in materials of interest. Finally, activities by the division in the area of lithium breeding blanket (LLB) development can be highlighted. This work is based on liquid metals (Li-Pb) or lithium based ceramics for LLB and on corrosion or permeation phenomena in blanket structural materials.

Materials for fusion applications

The radiation effect is one of the critical aspects concerning fusion reactor development. The neutron and gamma radiation produced in the reactors´vessels generates displacement defects and transmutations. Such micro-structural damage leads the materials to suffer degradation of its mechanical and physical properties. Embrittlement, swelling, stress corrosion cracking, hardening loss of optical transmission and of electrical isolation are some examples of the problems that radiation will cause on structural and functional materials used in ITER and DEMO. LNF drives fundamental research activities to approach the understanding of radiation effects in structural and functional materials of interest for fusion.

- Structural Materials: Candidate steels to build the reactor vessel while resisting loads, high temperatures, high radiation fluxes and intense magnetic fields.

- Materials for solid breeder blankets: For the HCPB (Helium Cooled Pebble Bed) design.

Material Irradiation Facilities

2 MeV ELECTRON VAN DER GRAAF ACCELERATOR

This facility permits either direct irradiation with 2 MeV electron or Bremsstrahlung irradiation produced by stopping the electron beam at beam currents up to 150 µA. In this way the same type of radiation testing that is carried out using Co-60 irradiation facility can be done but more rapidly (higher and well controlled dose rate) performing the corresponding measurements during irradition, in-situ. Irradiation parameters (temperature, vacuum, special gas environment, dose rate and beam energy) are strictly controlled. Irradiation of relatively big components or materials is possible. The same accelerator staff design and develop different irradiation chambers and experimental set-ups depending on irradiation characteristics. The developed experimental systems permit making optical, electrical and dielectrical measurements during irradiation ("in-beam"). Particularly, this is a unique experimental radiation facility in which simultaneous optical and electrical and dielectric measurements at between Hz and GHz can be made during irradiation. Systems to measure optical absorption and radioluminescence, electrical conductivity and dielectric properties during irradiation (in-situ) are mounted in the accelerator beam line

Beam characteristics;

Electrons, 0.25 to 2.0 MeV, 10 pA to 150 µA

Samples from ≈ 3 mm2 to about 20x20 cm2

At target area unfocussed beam is ≈ 1 cm diameter

Beam can be focussed to ≈ 1 mm diameter for very small samples

Beam can be defocussed to ≈ 3 cm diameter

Beam can be scanned over 20x20 cm2 for very large samples

The facility has been used for insulator work in which low dpa rates must be employed and where ionization is important. The facility includes in-beam testing at controlled temperatures in vacuum or different gas environments, for electrical, dielectric (RF), and optical properties of solid and gas insulators.

For insulator work typical dpa rates range from about 10-12 to 10-8 dpa/s and ionization rates (Bremsstrahlung or direct electron irradiation) 0 to ≈ 104 Gy/s For steels we can reach about 10-3 dpa/day in volumes of approximately 3x3x1 mm3.

Flexibility

The instalation is extremely flexible and has several unique in-beam systems for measuring electrical conductivity, dielectric loss and permittivity (Hz to GHz), and optical absorption and emission during irradiation over a wide range of dose rates and temperatures. Irradiations can be performed in high vacuum, air, or controlled atmosphere such as N or He. Simulation in electron accelerators offers important advantages, namely easy experimental parameter control and high dose rates available (0 a ≈105 Gy/s).

In-situ measurement capability and expertise. At this facility different studies on candiadate fusion insulators have been carried out, in particular electrical, optical and hydrogen and helium diffusion properties are measured routinously during irradiation, in-situ. These studies are carried out at controlled temperature, from liquid nitrogen up to 1000 C. Available special irradiation chambers and sample holders have been designed by the accelerator staff and fabricated at the Ciemat workshops. The irradiation can be performed either in vacuum or gas at controlled pressure. (helium, nitrogen, hydrogen etc).

60 keV DANFYSIK ION IMPLANTER

This facility permits ion implantation from 0 up to 60 keV with currents up 150 µA depending on the ion. Particularly helium, hydrogen and duterium has been implanted during the last years making use of this implanter for different tasks related with fusion research. The same implanter staff design and develop different irradiation chambers and experimental set-ups depending on implantation characteristics. The developed experimental systems permit making optical, electrical and desorption experiments in the implanter beam line, in-situ. Particularly simultaneous ionoluminescence and surface electrical conductivity measurements can be made allowing correlation between macroscopic material degradation and defects produced by implnatation.

Beam characteristics;

- 0 to 60 keV, up to 150 µA depending on ion.

- Samples from ≈ 3 mm2 to about 4x2 cm2

- At target area unfocussed beam is ≈ 1 cm diameter

The facility has been used regularly for metals and insulator work to implant helium, hydrogen, or deuterium to evaluate microstructural surface degradation, ionoluminescence, surface electrical degradation and to introduce helium and hydrogen isotopes to perform diffusion and desorption experiments.

In-situ measurement capability and expertise. At this facility different studies on candidate fusion insulators have been carried out, in particular electrical, optical and hydrogen and helium diffusion properties are measured regularly in-situ. These studies are carried out at controlled temperature, from liquid nitrogen up to 1000 C. Available special irradiation chambers and sample holders have been designed by the implanter staff and fabricated at the Ciemat workshops.

NAYADE Co-60 irradiation facility

For gamma rays irradiations CIEMAT has the ownership of a Co-60 facility with unrestricted access. The irradiations can be performed for long periods. The Nayade facility of CIEMAT is pool-type with water as biological shield. It consists of a pool of 1.2 m on side and 4.5 m deep of water, providing enough biological shielding for about 100,000 Ci of Co-60. The pool has the equipment and systems necessary to ensure safety controls through water level, radiation detectors, control of water purity through pH and conductivity measurements. These devices are controlled in a common console. The use of water as a biological shield allows direct vision of the bottom pool that is the surface where the radiation produced and facilitates the moving and positioning the sources and extraction of samples in the different devices.

The main irradiation characteristics in Nayade are:

- Type of source; 60Co cylindrical sources (15 mm diam. x 135 mm long)12 sources are distributed in a circular way providing an inner cylindrical irradiation volume.

- Two distributions are available:1.High flux; ≤ 8.3 103Gy/h within a 60mm diameter x 100 mm long volume. 2.Low flux; ≤ 1.2x102 Gy/h within a 200 mm diameter x 100 mm long volume (in the low flux configuration the sources rotate on an outer circle for uniform dose.

- Irradiations at controlled temperatures and atmospheres, together with in-situ testing of electrical properties are also possible.

- In this device the irradiations can be carried out at controlled temperature up to 300ºC. A gas flow (as dry air or nitrogen) can be introduce during the irradiations to prevent possible effect of humidity. The uncertainty dose rate is better than 20% in a volume about 283 cm3. A picture of the irradiation chamber (out of the irradiation pool) can be seen in figure.

Irradiation rigs are rotinously fabricated at Ciemat workshops in order to perform irradiations at different dose rates and conditions and to perform measurements during irradiations. The equipment and devices required to perform the irradiation tests, as sensors, signal cables, standard laboratory equipment, feedthrough, environmental monitors (temperature, pressure, humidity, radiation) are available Hardware and software with the function to acquire, record, transfer, store and process data acquired with the equipment of the irradiation test are available.

- Dosimetry system

The routine gamma dosimetry is performed using the commercially available Red Perspex™ 4034 Harwell dosimeters, they are polymethylmethacrylate (PMMA) dosimeters that have become widely used in routine high-dose rate dosimetry in the field of the industrial radiation processing. When exposed to ionising doses in excess of 1 kGy, the Red 4034 polymer starts to darken due to the formation of a new absorption band peaking at 615 nm and extending from 600 nm to beyond 700 nm. The absorbed dose is therefore determined by measuring its radiation-induced absorbance in the 630